Suspensions materials update

Different configurations

| 10-20K | 120K (Voyager style) | 300K (ET-HF) | ||

|---|---|---|---|---|

| Material | Silicon | Sapphire | Silicon | Silica |

| Intra cavity power | 18kW | 18kW | 3MW | 3MW |

| Mass | 200kg | 200kg | 200kg | 200kg |

| Wavelength | 1.5-2um | 1064nm | 1.5-2um | 1064nm |

| Remarks | Less progress in silicon research than expected before, costly and not sure if industry will supply it | Absorption challenging (KAGRA issues) | ||

| Pro | better for cryogenic | Can use 1064 with sapphire | Cheaper and easier from cryo standpoint, only need nitrogen no need for helium | |

| Con | Have to use 1.5/2um lasers | absorption not well understood |

Open points

- 2-photon absorption at 1550 ?

- ET @ 120K ?

- Silicon/Sapphire discussion (Issues with absorption / scattering?)

- Beam diameter for ET? Why do we have 9cm beam radius in the ET DS, when the substrates are only 45 cm diameter?

- What is 2 photon threshold (Between 20kW and 3MWs)? May be around 3MWs for 1550. Determines which wavelength to use as this is a problem for 1.5um but not 2.1um. 1.5um currently more well developed though.

- Scale 120K system into ET envelope. What is to be gained from 120K to 10k-20K, is it worth it?

- Substrate facility? Can’t control the substrates at the moment. What is the approximate cost/Is it feasible. Would need the polishing expertise/equipment too. Need cost benefit analysis of going to industry vs own facility. May be more expensive than a coating facility?

- Silicon fibres? Cut from wafers or pull through die. One company has done 1mm round cross-section 60mm(?) long fibres like this pulled already. Impurities may be a problem. Sapphire easier to grow. laser heating absorption in sapphire better.

Coatings

- Absorption of aSi @ 120K ? (25ppm @ 300K)

- Absorption of aSi at 2um lower by factor 7 than 1.5um (Iain Martin)

- aSi coatings only small scale at the moment

General materials

- Sapphire bulk absorption is currently an issue, not certain if it will be fixed or not. Unreliable (sometimes low, sometimes not).

- Reason for absorption may be refractive index changes not contaminants. Bubbles? Has happened

Hybrid suspension

- Si/Si02: 3x worse thermal at 120K at 10Hz

- Si/Sapphire: Thermal mismatch? Can be bonded. Keep in mind length of sapphire fibres

Composite masses

- What would be a practical shape?

- HCB to connect, faces need to be polished after each bond step and a new piece added

- In afternoon discuss composite masses for substrates. Core of low absorption material, other materials on outside, etc

- Possible to use higher order modes and put bonds in dark

- Difficulties: Have to match phase, be careful about astigmatism

Fibres

- Silicon: Fibres produced but not characterized

- R&D required on strength/loss

- Prototype needed (GEO → aLIGO took us 10-15 years)

- Usage of laser for Silicon requires probably dual heating system → Start with 10.6um, but 10.6 not usable once heatet above melting point → Silicon changes emittance. Is 1064nm better suited?

Cooling times

- Conductive cooling (20K) versus Radiative cooling (120K)

Thurs. 7th September

Useful links

- silicon suspension paper: http://iopscience.iop.org/article/10.1088/0264-9381/31/2/025017/meta

Some thoughts (from Norna)

For 2 Hz design in particular we should not forget that other modes of the suspension/isolation system may appear above 2 Hz. This could be longitudinal modes from stage(s) just above the final 2m long stage and other modes (e.g. pitch and vertical) which couple significantly into longitudinal direction.

(Reminder - the aLIGO quad design has 22 modes between ~0.4 and 5 Hz, and highest vertical and roll around 10 and 14 Hz)

Can probably get most modes below 2 Hz by careful design (and long lengths) - but vertical/roll not so easy.

Over 10 km arm length vertical coupling will be ~0.2% from curvature of Earth.

We can look at the expected vertical frequencies for different parameters, and consider feasibility of adding blades/springs in the final stage to achieve < 2 Hz.

Material properties

| property | Fused silica | Silicon | Sapphire |

|---|---|---|---|

| Young's modulus (GPa) | 72 | 188 | 400 |

| Poissons ratio | 0.17 | 0.22 | 0.3 |

| density (kg/m3) | 2202 | 2330 | 3980 |

| refractive index | 1.45 | 3.453 | 1.75 |

| Material | Temperature (K) | Thermal expansion (1/K) | Thermo-optic coeff. (1/K) at 1500nm | beta (1/K) at 1000nm | Specific heat (J/kg/K) | Thermal conductivity (W/m/K) | Thermal diffusivity (m2/s) | Volumetric thermal stability (m2 K/s) |

|---|---|---|---|---|---|---|---|---|

| Fused silica | 10 | -2.04e-7 | 3.38e-7 | 3.48e-7 | 4.16e0 | 1.27e-1 | 1.39E-05 | 6.80E+01 |

| Fused silica | 20 | -6.11e-7 | 6.75e-7 | 6.96e-7 | 2.45e1 | 1.53e-1 | 2.84E-06 | 4.65E+00 |

| Fused silica | 120 | -4.75e-7 | 4.19e-6 | 4.21e-6 | 3.39e2 | 8.04e-1 | 1.08E-06 | 2.27E+00 |

| Fused silica | 300 | 3.43e-7 | 8.57e-6 | 8.6e-6 | 7.61e2 | 1.38e0 | 8.24E-07 | 2.40E+00 |

| Material | Temperature (K) | Thermal expansion (1/K) | Thermo-optic coeff. (1/K) | Specific heat (J/kg/K) | Thermal conductivity (W/m/K) | Thermal diffusivity (m2/s) | Volumetric thermal stability (m2 K/s) |

|---|---|---|---|---|---|---|---|

| Silicon | 10 | 5e-10 | 8.4e-8 | 2.76e-1 | 2.11e3 | 3.28E+00 | 6.57E+09 |

| Silicon | 20 | -3e-9 | 1.52e-6 | 3.41 | 4.94e3 | 6.22E-01 | 2.07E+08 |

| Silicon | 120 | -6e-8 | 9e-5 | 3.28e2 | 6.38e2 | 8.36E-04 | 1.39E+04 |

| Silicon | 300 | 2.62e-6 | 1.91e-4 | 7.13e2 | 1.48e2 | 8.92E-05 | 3.40E+01 |

| Material | Temperature (K) | Thermal expansion (parallel) (1/K) | thermal expansion (perpendicular) (1/K) | Specific heat (J/kg/K) | Thermal conductivity (W/m/K) | Thermal diffusivity (m2/s) | Volumetric thermal stability (m2 K/s) |

|---|---|---|---|---|---|---|---|

| Sapphire | 10 | 7.5e-10 | 3.75e-10 | 8.74e-2 | 2.9e3 | 8.34E+00 | 1.11E+10 |

| Sapphire | 20 | 6e-9 | 3e-9 | 7.98e-1 | 1.57e4 | 4.94E+00 | 8.24E+08 |

| Sapphire | 120 | 1.52e-6 | 9.42e-7 | 1.63e2 | 3.34e2 | 5.15E-04 | 3.39E+02 |

| Sapphire | 300 | 5.9e-6 | 5.15e-6 | 7.92e2 | 4.6e1 | 1.46E-05 | 2.47E+00 |

From ET design study (ET-0106C-10) and database of bulk material properties(ET-0001A-14, Heinert et al).

Vertical (bounce) mode calculations

This assumes fibre length of 2m, diameter 3mm, mass 200kg, and penultimate mass also 200 kg.

| Fused silica | Silicon | Sapphire |

|---|---|---|

| 16.1 | 24.6 | 35.1 |

Stress is ~ 70MPa. This is reasonable value for silicon (at present).

We can increase stress/reduce diameter for silica and sapphire. e.g. silica with 0.8 mm diameter gives 4.3 Hz (stress ~ 1000MPa), sapphire with 0.9 mm diameter gives 10.5 Hz (stress ~ 800MPa).

To reduce vertical frequency from these values without other changes we would need to add springs/blades.

Violin mode calculations

Fundamental violin modes (Hz) based on fibre length of 2m, diameter 3mm, masses 200kg, for different materials (fused silica (density 2200kg/m3), Silicon (2328kg/m3) and Sapphire (3980kg/m3):

| Fused silica | Silicon | Sapphire |

|---|---|---|

| 44.4 | 43.2 | 33 |

With the above assumptions of increasing stress/reduce diameter for silica and sapphire. e.g. silica with 0.8 mm diameter gives violin mode frequencies of 166.5Hz (stress ~ 1000MPa), sapphire with 0.9 mm diameter gives 110Hz (stress ~ 800MPa)

Suspension TN script

These scripts requires access to the speedmeter SVN for access to validation functions calcsusthermnoise.m plottestmasssusthermnoise.m ssmparameters.m

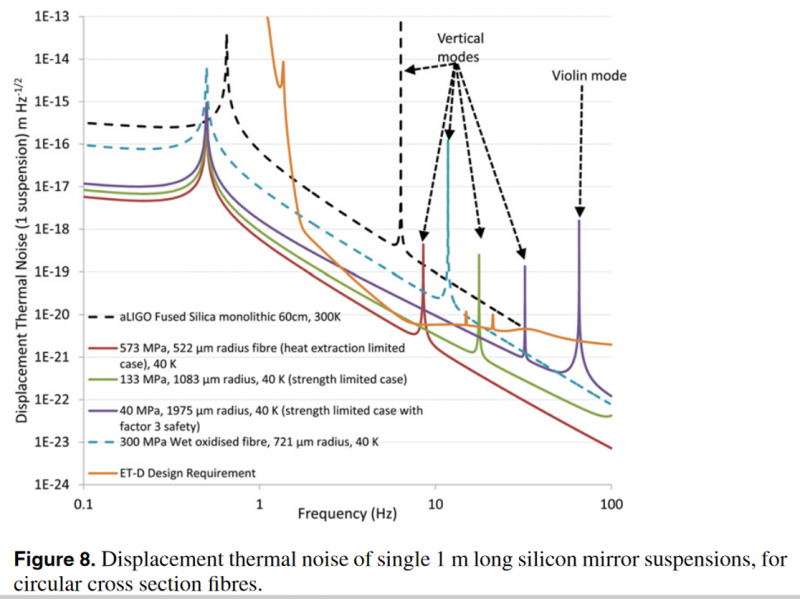

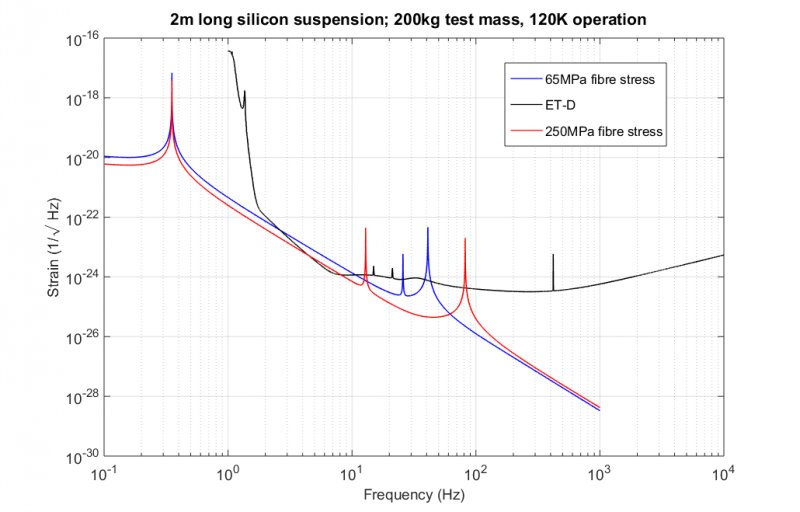

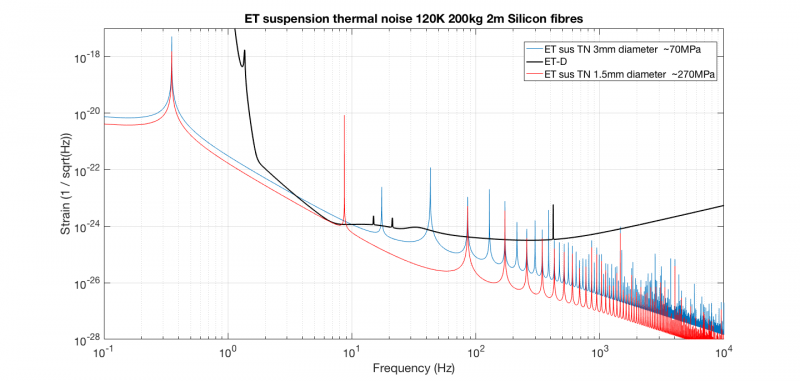

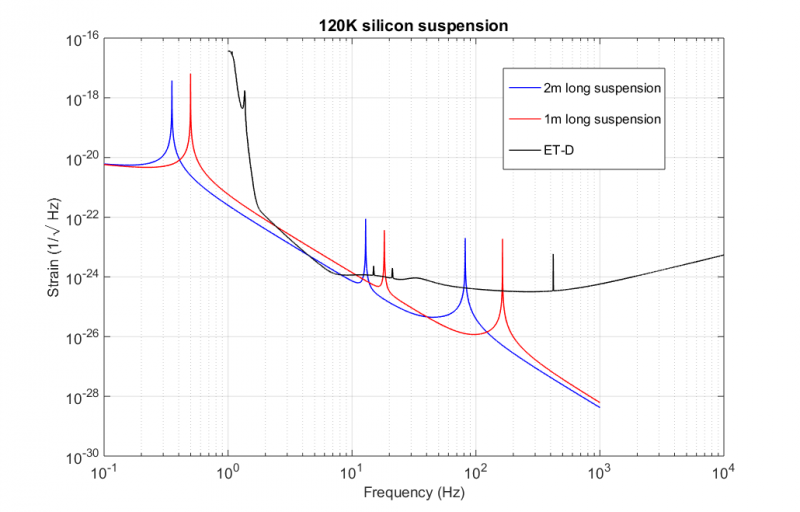

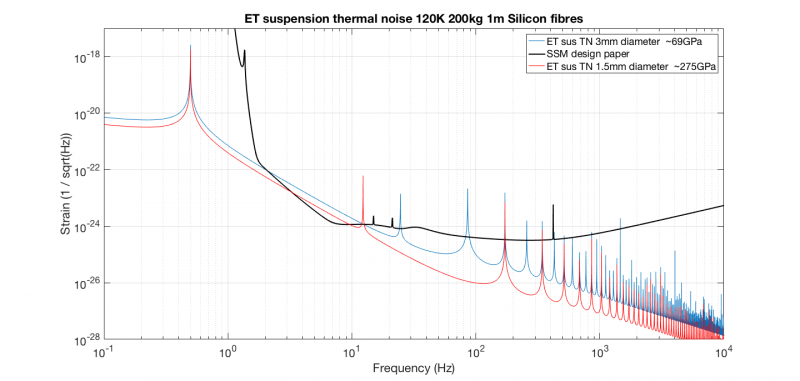

Jan and Giles worked on modelling the lower stage suspension thermal noise. Two codes were used and these gave identical numbers to 10%. This figure shows suspension thermal noise of a 120K system with 2m long silicon fibres. A fibre stress of 65MPa (demonstrated) and 250MPa are given. R&D will be required to show that long fibres can be fabricated with high tensile stress. Possibilites include zone refining and pedestal growth to grow pristine material (the current breaking stress is for etched surfaces).

Note: bounce/violin modes are close together for low stress operation. Note: these estimates DO NOT include attachment loss. This needs to be estimated/modelled for a robust thermal noise estimate.

Preliminary plots:

A comparison was also made with different suspension lengths. These plots assume a fibre stress of 250MPa (red curve in previous plot)

Two Photon absorption in Silicon @ 1550 nm

Fri. 8th September

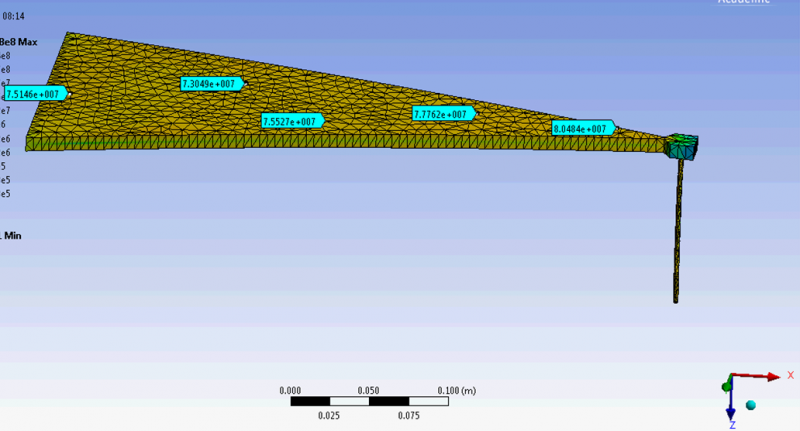

Preliminary spring modelling

We carried out some spring modelling on triangular blade profiles with 50kg mass. A 0.2m base width x 9mm thick x 0.4m long triangular blade of silicon, gives bounce mode frequency 5.57Hz. There's approximately a factor 4 safety margin w.r.t. failure stress.

| Material | Width / m | thickness / m | length /m | f_0 / Hz | Stress / MPa | Ratio stress to failure stress |

|---|---|---|---|---|---|---|

| Silicon | 0.2 | 9e-3 | 0.4 | 5.57 | 72 | 0.24 |

| Silicon | 0.2 | 8e-3 | 0.4 | 5.0 | 92 | 0.31 |

| Silicon | 0.2 | 7e-3 | 0.4 | 4.1 | 120 | 0.40 |

Spring stress with 50kg load in ANSYS

Next steps

1. Model bond loss in suspension (full FEA model)

2. More work needed on passive/active isolation techniques within ET (not done at this workshop)

3. Modelling of springs/lower stage

Longer term

1. R&D on silicon fibres

2. small scale prototype development

3. Sensors & Actuators with good low temperature performance (interferometric?, piezo inch worms?)