A+ Coating Research

updated July 2018

Authors: Iain Martin (UoG), Stuart Reid (UoS).

Mechanical loss measurements by Svetoslava Angelova (UoS).

Coatings manufactured at UoS by Svetoslava Angelova and Ross Birney.

Photothermal absorption measurements carried out at UoG by Simon Tait.

Ellipsometry measurements carried out at UoG by Iain Martin and Svetoslava Angelova.

Holding page for results for zirconia-tantala alloy coatings, from the Strathclyde, Glasgow and UWS groups.

Introduction:

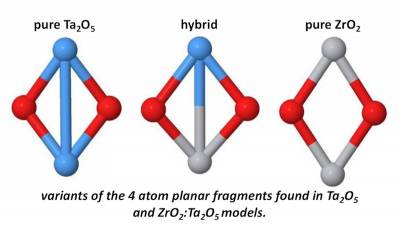

Improvements in the mechanical dissipation from iLIGO to aLIGO were associated with mixing alloys of titania and tantala, with correlations observed between the mechanical loss and the the ratio of hybrid “fragments” within the amorphous atomic network. Alternative metallic oxides have been proposed which could further reduce mechanical dissipation. Zirconia-tantala has been proposed for the following reasons:

- Atomic simulation work carried out at the University of Glasgow (Glasgow group and particularly K. Evans, R. Bassiri, and K. Borisenko (Oxford)) predicted that alternative metal species, such as zirconium, could alter the dynamical behaviour of the hybrid fragments shown below and thus further reduce the mechanical dissipation.

- Marty Fejer (Stanford) and Steve Penn (HWS) also identified zirconium as a stabilising alloy which could be used to increase the crystallisation temperature, and thus provide routes to subject mirror coatings to higher heat treatment temperatures (typically higher heat treatments reduce the mechanical dissipation, however titania-tantala alloys will typically crystallise by 700C (Iain to add reference to Zr stabilisation against crystallisation).

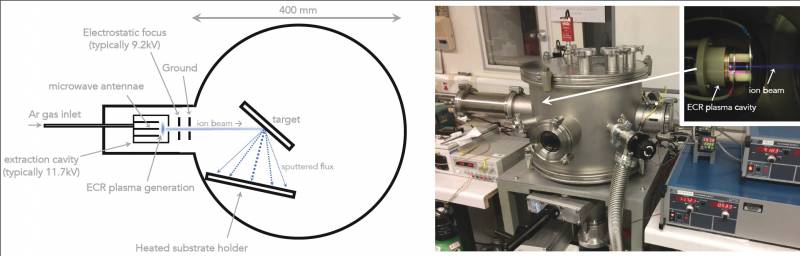

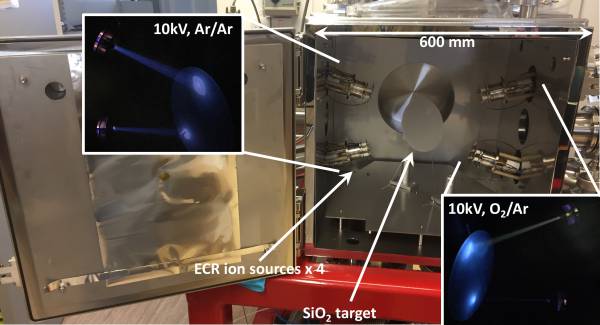

Ion beam deposition system at Strathclyde

In collaboration with Glasgow and UWS, and colleagues elsewhere in the LSC, a novel ion beam deposition facility has been created at the University of Strathclyde (within the group led by Stuart Reid). Ion beam deposition has (thus far) been the only deposition technique that can satisfy the optical requirements for LIGO, over the areas required. The Strathclyde lab has therefore developed an ECR (electron cyclotron resonance) ion beam deposition system with increased flexibility as compared to commercial systems. This will enable the investigation of a wide range of deposition conditions for research towards the A+ coatings (and beyond). Alongside this, the facility has demonstrated the first elevated temperature ion beam deposition, with a recent paper published by Caltech, Strathclyde and LSC colleagues (http://iopscience.iop.org/article/10.1088/1361-6382/aaad7c/meta).

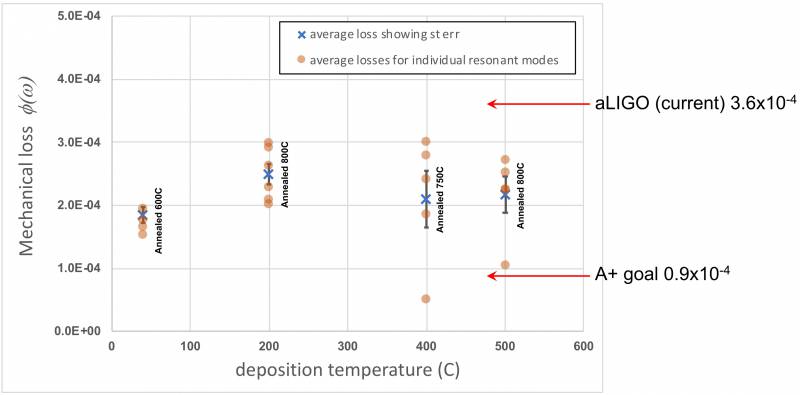

Mechanical loss measurements

The following plots below show examples of the mechanical loss measured in zirconia-tantala, showing that losses below ~2e-4 may be achievable in these thin film coatings. Mechanical losses were measured using the ringdown method on fused silica cantilevers (approx 150um thickness, 40mm length). The Zr content was measured to be 8-9% by WDX.

It is important to note the following:

- All coating thicknesses were directly checked on each silica cantilever using the Glasgow ellipsometer.

- We see evidence of run-to-run variation in our prototype IBD chamber and therefore there may be deposition parameters that we are not precisely controlling e.g. target and substrate positions/angles.

- We assume that the mechanical loss will be independent on layer thickness. The mirror stack will require ~120nm thickness layers of high index material, as compared to the 300-500nm thickness used in the mechanical loss measurements presented here. This will need to be investigated further by the Strathclyde-Glasgow groups and cross-checked by other LSC labs.

- It could be expected that the mechanical loss of the silica layers would be further reduced by heat treatment to 750C, compared to 500C for Advanced LIGO (See S. Penn work, G1300776), and therefore further enhancements might be expected in the multilayer stack due to the increased annealing temperature on the silica layers.

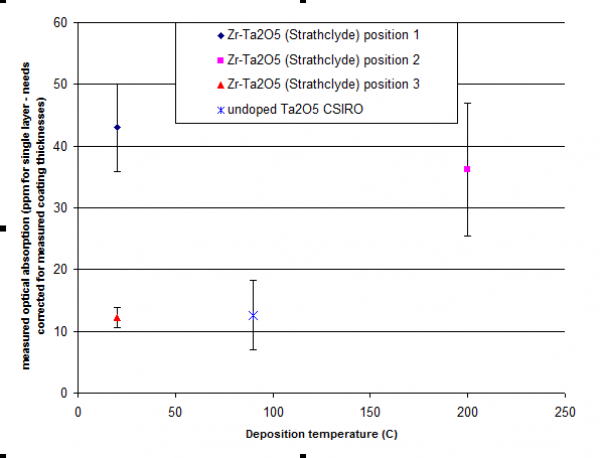

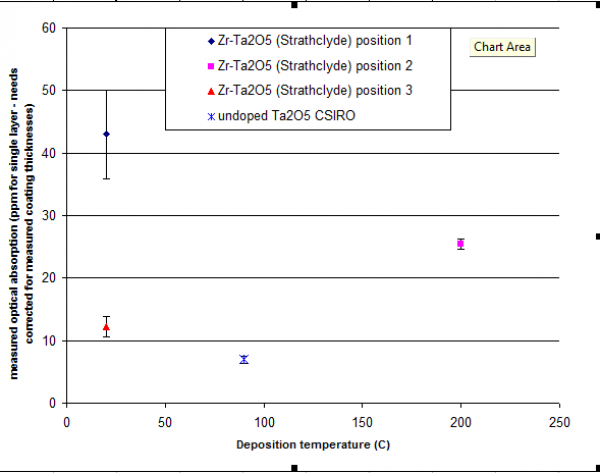

Optical absorption measurements

Preliminary absorption measurements have been carried out. The plot below compares the zirconia-doped tantala to an as-deposited undoped tantala IBS coating from CSIRO, at 1064nm. One would expect the absorption of all coatings to reduce with heat-treatment, and the CSIRO coating would be expected to achieve the absorption required for use in aLIGO. That is, the typical reduction in optical absorption observed in tantala films through heat heat treatment would reduce from 10-30ppm measured absorption to ppm or sub-ppm.

Further details on deposition parameters

There exists a large parameter space to be investigated regarding optimum deposition conditions. At Strathclyde, the following parameters can be investigated:

- Extraction potentials up to 15kV, with associated energy in sputtering plume (yet to be characterised)

- Flexibility in plasma has species (the sputtering gas) used (at the moment only Ar)

- Reactive gas species and pressure (only O2 gas investigated, at a reactive pressure around 2.4e-4 mbar, which is optimum for the O2 pressures investigated thus far)

- Target geometry and composition (currently 99.99% purity Ta2O5 4” target, with 99.99% purity Zr foil strip)

- Deposition temperature - up to 500C

- Annealing temperature

Future plans

We are commissioning a new (larger) ECR-IBD system which will enable larger area coatings to be deposited (4 x 4” wafers), which will allow disk measurements on a nodal support to be conducted too. The new system had rotational staging installed in June 2018, to improve coating uniformity. Planetary motion will be installed over the coming months. We plan to repeat Zr:Ta2O5 coatings in the new system and verify the repeatability of the above results.

Image of the new set up: